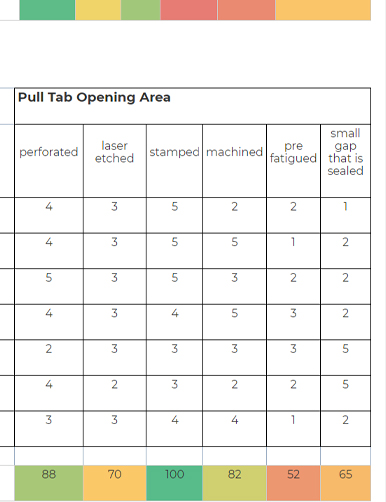

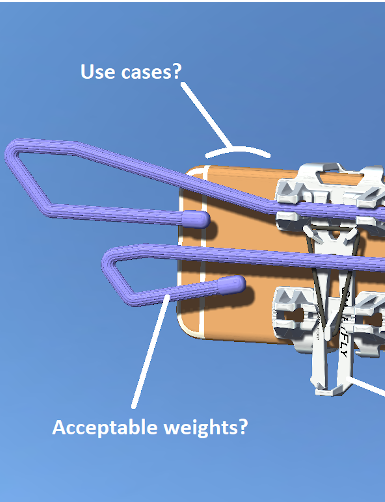

What Did We Make and Why - Concepting/Ideation

What Did We Make and Why - Concepting/Ideation

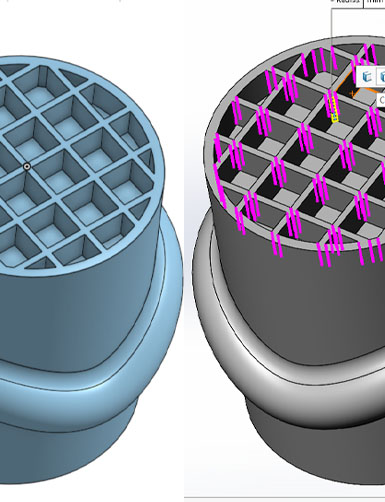

View Full PostThe Subtleties of Draft Angles and Injection Molding

The Subtleties of Draft Angles and Injection Molding

View Full PostSwitched On: MOSFET Selection Guide

Switched On: MOSFET Selection Guide

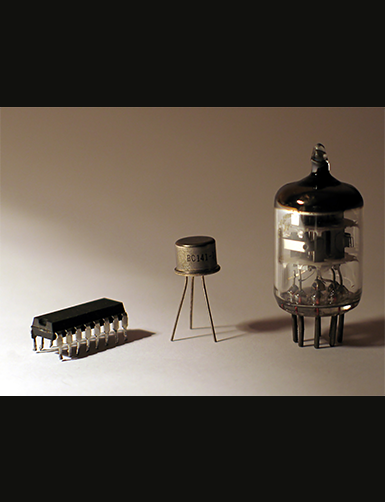

MOSFETs (metal-oxide semiconductor field-effect transistors) are heavily used in a most of the electronics we use every day. When looking at it from a sheer numbers perspective, the vast majority are contained within what is known as an integrated circuit. These parts can contain anywhere from hundreds to billions of the devices on a single chip and perform a myriad of different functions.

View Full PostHigh Speed Signal Integrity in FPCs

High Speed Signal Integrity in FPCs

Modern PCB manufacturing in FR4 provides designers with an incredible range of control, and has become a familiar and mature technology. However, many applications have mechanical requirements that conflict with the rigid, planar geometry inherent in PCBs. Flexible printed circuits, or “FPCs,” offer an alternative to conventional PCB substrates and allow for a broad range of applications that would otherwise be impossible or impracticable to produce.

View Full PostDesign and the Environment

Design and the Environment

As a product design firm, we strive to make the best and longest-lasting products possible. We aim to make successful products that fulfill the customer’s needs and requirements while maintaining some element of beauty. This, as expected, requires an extensive amount of planning, research, prototyping, foresight, and knowledge of the consumer base.

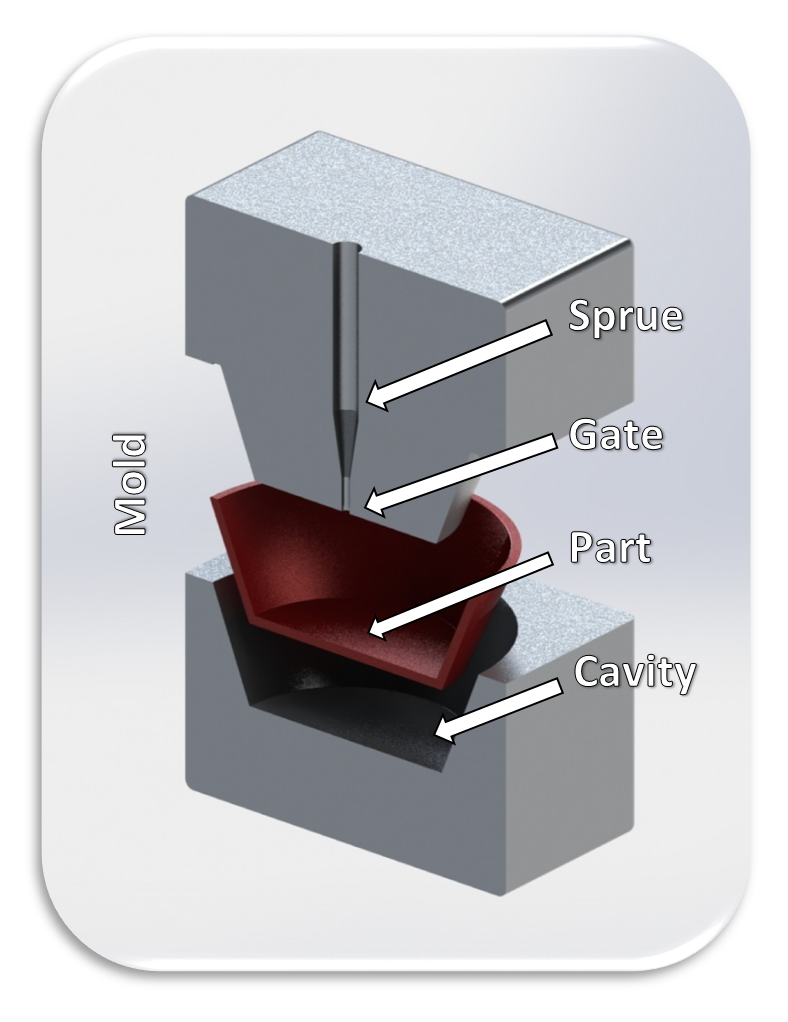

View Full PostInjection Molding: A Quick Primer

Injection Molding: A Quick Primer

If you’re reading this, I can guarantee you are either holding, using, and/or wearing something that has been injection-molded. Injection molding is the most prevalent manufacturing technique for most products manufactured at high volumes and includes everything from the very tiny, like the power button on your phone, to the very large, like the plastic storage bins in your closet or under your bed.

View Full Post.svg)