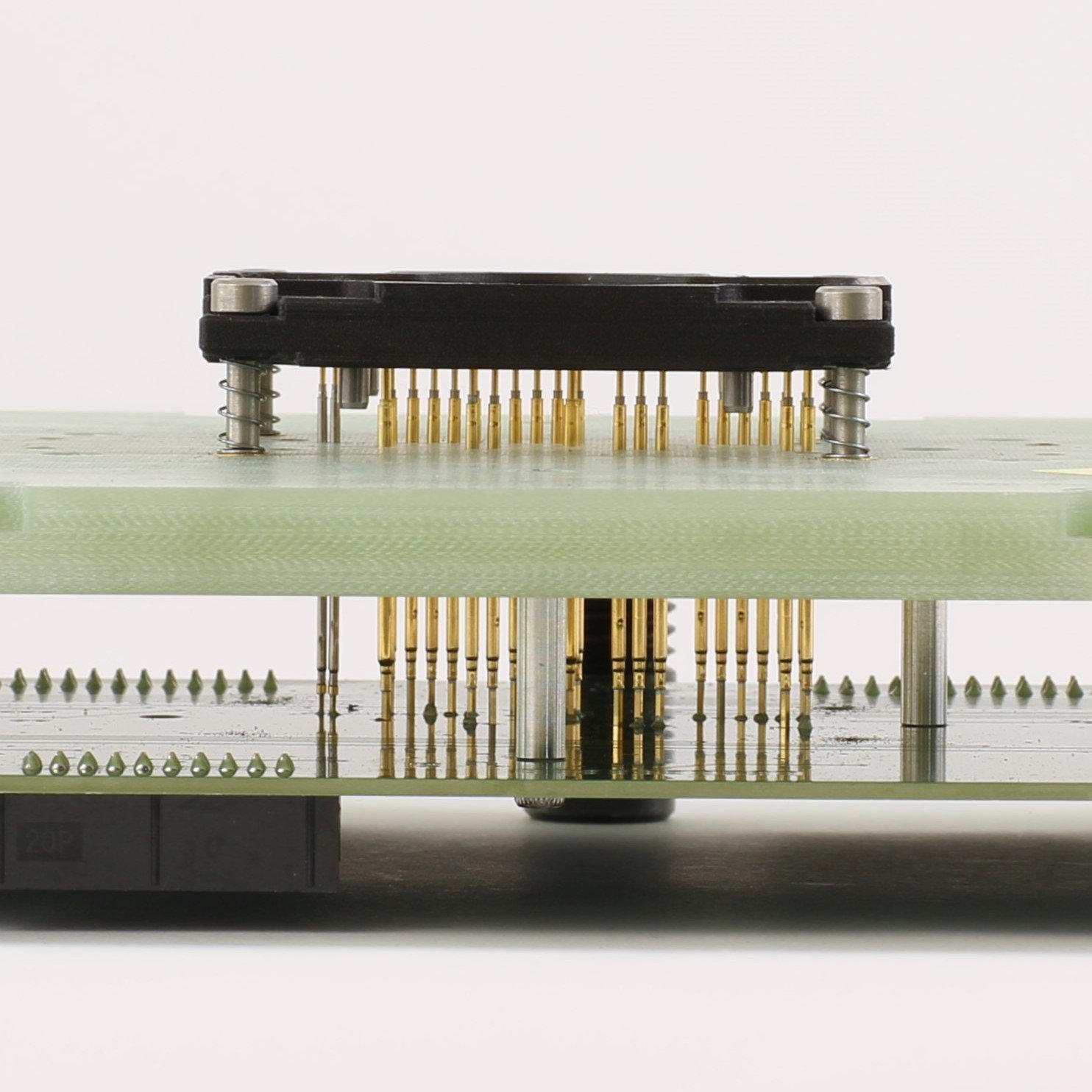

Base Fixture Frame: BT201-F50-00A

$1,980.00Base Open Frame with blank Pogo-Plate & Acrylic top (generally ships next-day)

Save countless hours of debugging that used to come with the rats-nest of airwires. Measure actual performance rather than rely on simulations.

Program and test devices in single or multi-gang configuration with consistency and high quality results. Report results directly to your systems or the customers.

Access systems and modules reliably, focusing development on as-built designs instead of cobbled- together development kits. Triage real issues in real time.

Monitor, track, and report passes; identify, log, and quarantine failures. Ensure a robust regulatory compliance in NPI, production, and end-user returns.

The BES Fixture platform is just that—a platform. Buy a base platform, work with BES to integrate your existing elements, or have BES design it all. Unsure what your needs are? Click the link below to start a discussion with us.

BES considers three core elements when designing a Fixture: the DUT Interface, the Control Board, and the Test Runner. Depending on your project's needs and complexity, you might need some or all of these elements. Read about them below and see which ones are right for you.

______

Pogo plate assemblies ensure precise access to even the most dense test points without sacrificing reliability. Custom nests securely hold the DUT during tests, while allowing quick access before and after.

______

Control Boards provide power, communication, and testing capabilities to your DUT, and interface with your external peripheral devices such as screens, programmers, and barcode scanners. Minimized cable and routed trace lengths optimize signal integrity and reduce signal latency.

Custom-built. Interchangeable design blocks produce boards for your test needs.

Reliable. Onboard circuitry minimizes cable lengths and programming errors.

Documented. BES’s experience and layout library result in fast, robust designs.

Interfaceable. Customizable headers ensure painless, quick setup and access.

______

Flexible signal-switching fabric integrated with custom Test Runners allows signals from multiple DUTs to share endpoint-measuring circuitry–minimizing hardware cost while maximizing test parallelism. Custom-test running software determines DUT fitness, logging, and recording status, locally or to a remote endpoint. Easily-adjustable interactive GUIs provide operator instruction and smooth deployment.

Note: The following list does not include all DUT features that BES can test, this list only provides examples of some of BES’s capabilities. Please reach out if you have questions about DUT features not included in the list.

Note: If you have a desired feature not addressed in this list or the DUT features FAQ, please reach out and inquire.

BES has developed a low-cost and parallelizable SWD programming solution, suitable for many modern microcontroller families. Integration and parallelization of first-party and third-party programmers (J-Link, etc.) can also be implemented. Hardware cost, development effort, payload size, and required speed determine the optimal programming solution.

Currently BES offers the following accessories as turnkey components:

BES also offers design and sale of custom accessories for fixtures. Reach out to us to start a discussion!

BES recommends a maintenance interval of 250,000 cycles. Maintenance consists of gas spring replacement, and can be accomplished in-field in approximately 10 minutes. Total frame life has been documented to exceed 2 million cycles.

Note that this rating is for the mechanical frame. Pin cycles will vary by component, but can typically be replaced or refurbished without device disassembly.

Base Open Frame with blank Pogo-Plate & Acrylic top (generally ships next-day)