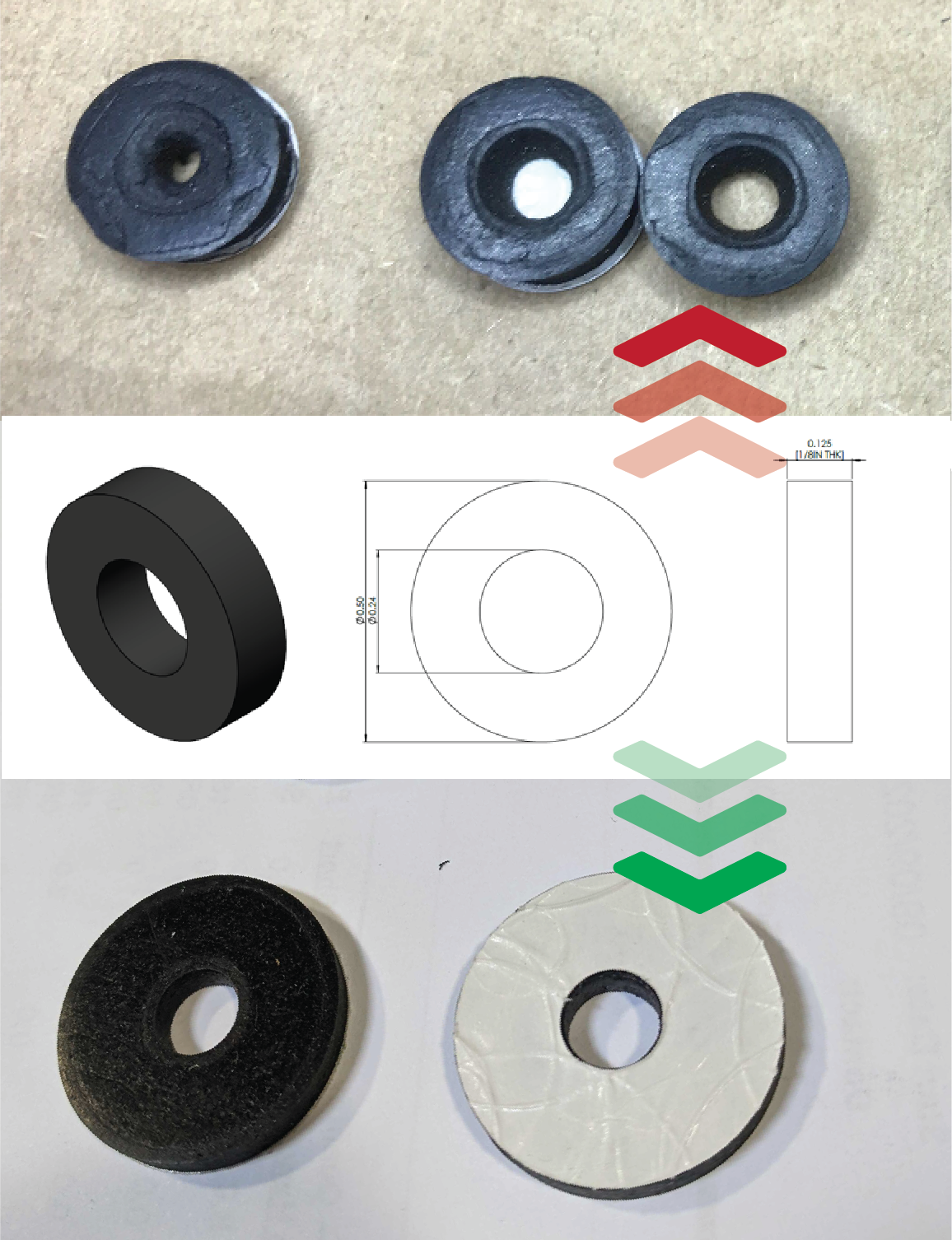

Scaling Up and the Nuances in Die Cut Design

Scaling Up and the Nuances in Die Cut Design

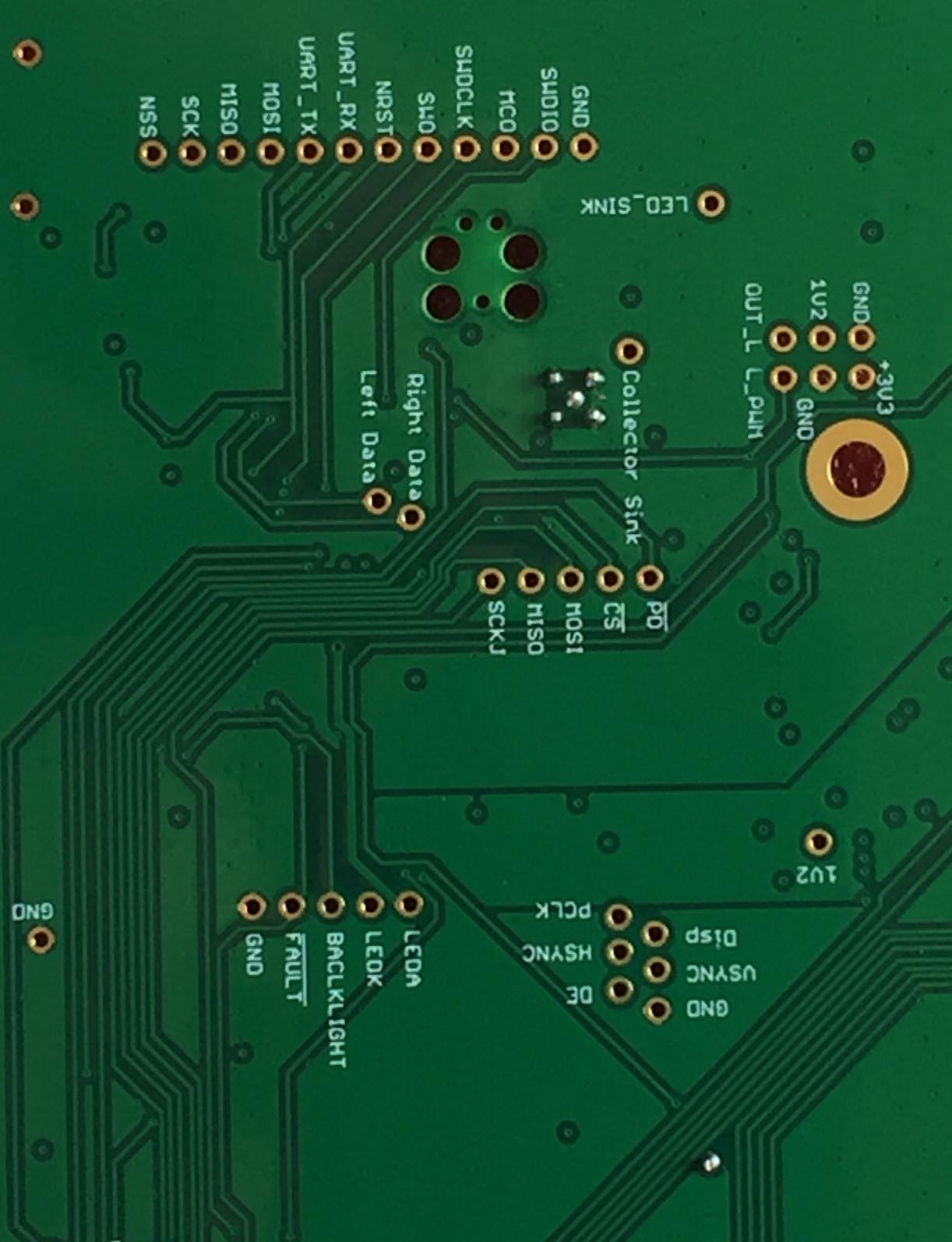

View Full PostPCB Silkscreen: Consider your Stakeholders

PCB Silkscreen: Consider your Stakeholders

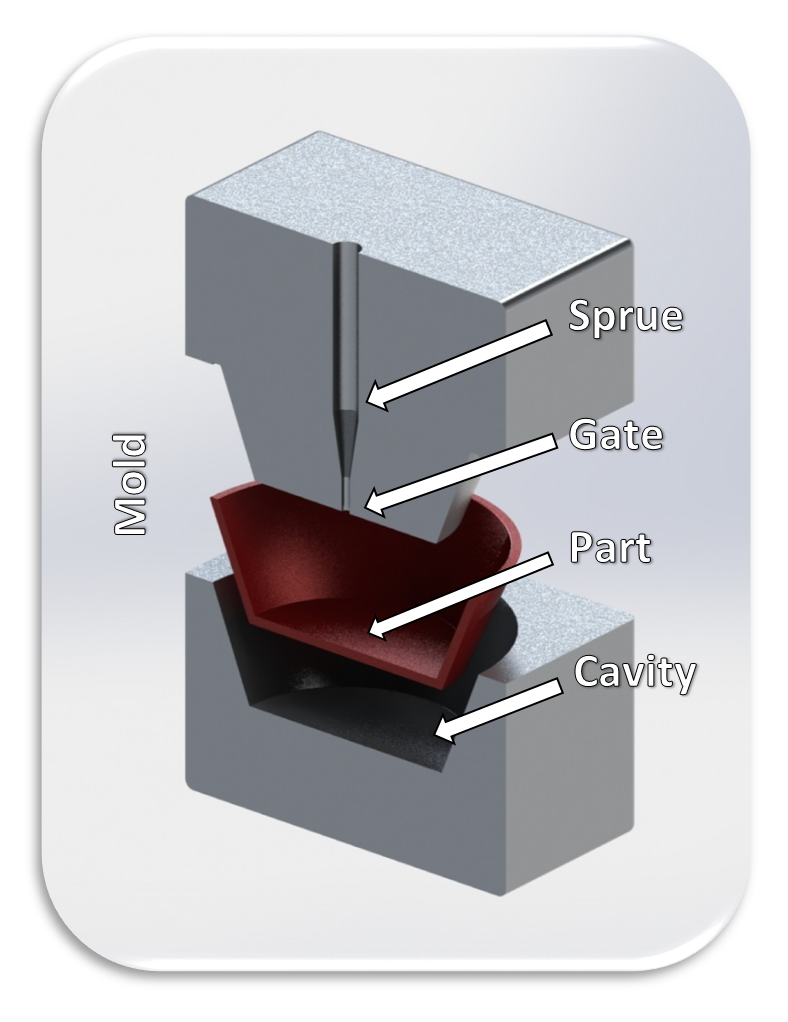

View Full PostThe Subtleties of Draft Angles and Injection Molding

The Subtleties of Draft Angles and Injection Molding

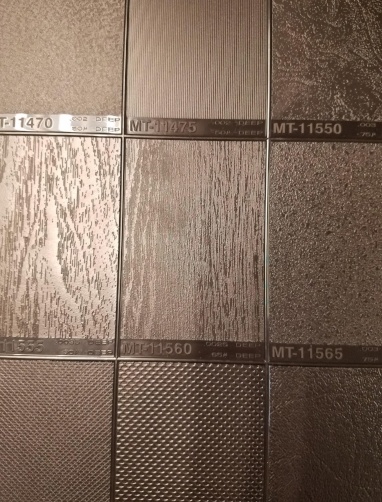

View Full PostPlastic Part Decoration

Plastic Part Decoration

lastic parts like those used in almost every consumer product are often left bare—they pop out of the injection mold and are assembled into their final product. This is the most cost-effective means of producing injection-molded parts but restricts them to the color of the bulk material and textures of the mold itself.

View Full PostFinishing An Injection Molded Part

Finishing An Injection Molded Part

If you look at any of the plastic parts immediately around you, chances are that most of them have been injection molded. Of course, if you’re at a Boulder climbing gym, most of the plastic there is a little different—it’s poured. In any case, you’ll notice that not only do many plastic parts look very different, but they feel very different too. The surfaces and textures on plastic parts may span a large range of common options in the injection molding industry.

View Full PostInjection Molding: A Quick Primer

Injection Molding: A Quick Primer

If you’re reading this, I can guarantee you are either holding, using, and/or wearing something that has been injection-molded. Injection molding is the most prevalent manufacturing technique for most products manufactured at high volumes and includes everything from the very tiny, like the power button on your phone, to the very large, like the plastic storage bins in your closet or under your bed.

View Full Post.svg)